Notifications

3 minutes, 10 seconds

-9 Views 0 Comments 0 Likes 0 Reviews

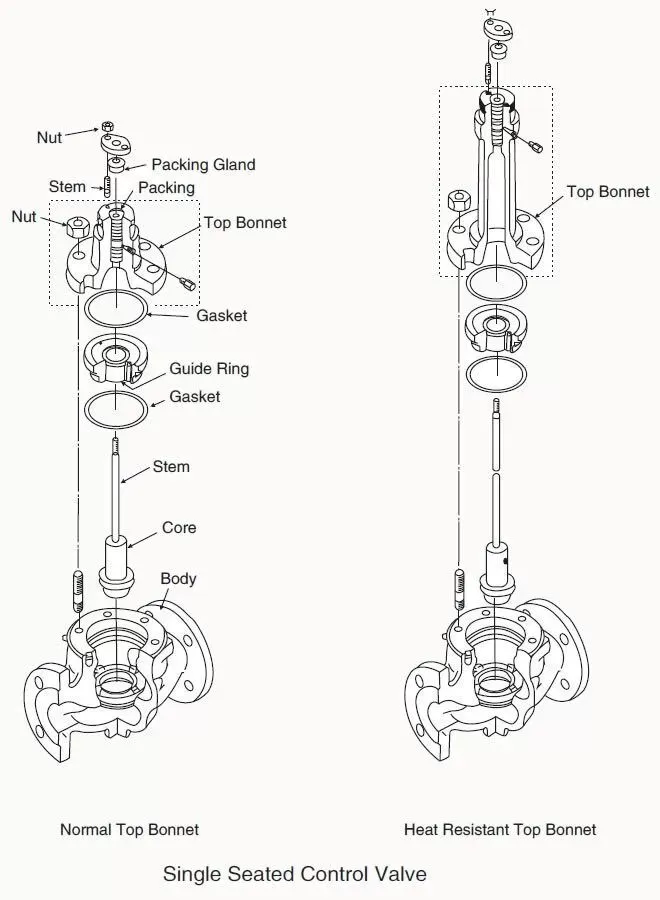

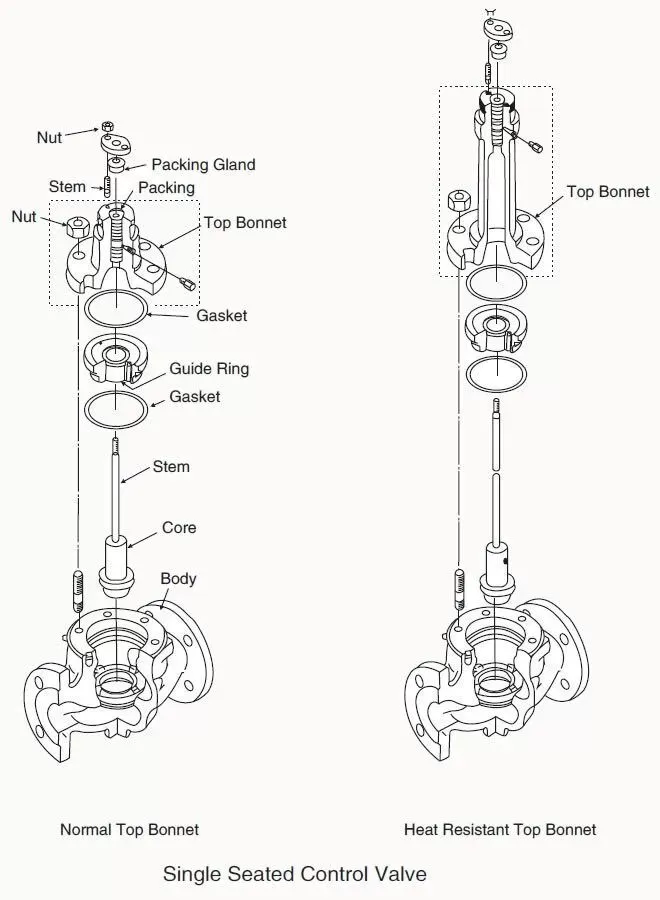

Single-port, single-seated control valves are vital components in industrial processes, engineered to provide precise flow regulation and reliable shut-off across diverse applications. Designed for heavy-duty service, these China Control Valves feature a compact body with an S-shaped flow passage that minimizes pressure loss while optimizing flow capacity, rangeability, and flow characteristics.

Valve Body: The compact valve body incorporates an S-shaped flow path that reduces pressure drop and improves flow efficiency, enabling the valve to handle large flow rates with minimal turbulence.

Valve Plug or Disc: The flow-controlling element is supported by a robust top guide section, ensuring excellent stability and vibration resistance. This design complies with stringent IEC or JIS standards for shut-off performance.

Actuator: Typically equipped with a diaphragm actuator loaded with multiple springs, these valves deliver reliable force and responsive operation under varying pressures and temperatures.

Single-seated control valves are used extensively across multiple industries, including:

Petrochemical and chemical processing

Pharmaceutical manufacturing

Food and beverage processing

Power generation

They effectively regulate liquids, gases, and steam, thanks to their durable construction using materials like stainless steel or carbon steel, which ensure compatibility with harsh or corrosive environments.

To meet diverse process needs, these valves offer various trim designs and materials, such as:

High-capacity or precision-contoured plugs

Equal percentage or linear flow characteristics

Soft seats or metal seats

This flexibility allows customization of flow capacity and control precision tailored to specific applications.

Precise Control: Their design ensures accurate and reliable flow regulation, critical for process efficiency and product quality.

Throttling Capabilities: Smooth modulation of flow rates allows for fine adjustments as required by the process.

Reliable Shut-Off: Tight sealing when closed prevents leakage, enhancing safety and operational integrity.

Versatility: Capable of handling corrosive liquids, high-temperature gases, and abrasive slurries, suitable for a wide range of fluids and conditions.

Straight-Through Flow: The flow path reduces pressure drop and flow disturbances, improving energy efficiency and process stability.

These valves typically provide an inherent rangeability of 50:1, meaning they can control flow effectively from full open down to 1/50th of the maximum flow. Some designs extend this capability to 75:1, enabling precise control even under widely varying process conditions.Know more about Google SEO Directory