Notifications

5 minutes, 37 seconds

-6 Views 0 Comments 0 Likes 0 Reviews

Used beverage cans (UBCs) are a prevalent waste source in our daily lives, originating from various places such as households, restaurants, bars, and public venues. UBCs come in multiple types based on materials:

Aluminum - based: The majority of traditional beverage cans are made of aluminum due to its lightweight, corrosion - resistance, and high recyclability.

Plastic - based: Many bottles for drinks like water, soda, and juice are made from plastics such as PET (polyethylene terephthalate), which are flexible and cost - effective.

Glass - based: Some beverages, especially premium ones like certain beers and juices, are packaged in glass bottles, known for their impermeability and ability to preserve flavor.

The conventional treatment of UBCs recycling solution generally includes collection, sorting, cleaning, and melting for reuse.

Both plastic - attached beverage cans and pure aluminum cans, including those with aluminum pull - rings, are recyclable. However, handling a large volume of beverage bottles through manual sorting presents significant challenges:

Time - consuming: Manually distinguishing between different materials and types is a slow process.

Labor - intensive: It requires a large amount of human effort, increasing labor costs and reducing overall recycling efficiency.

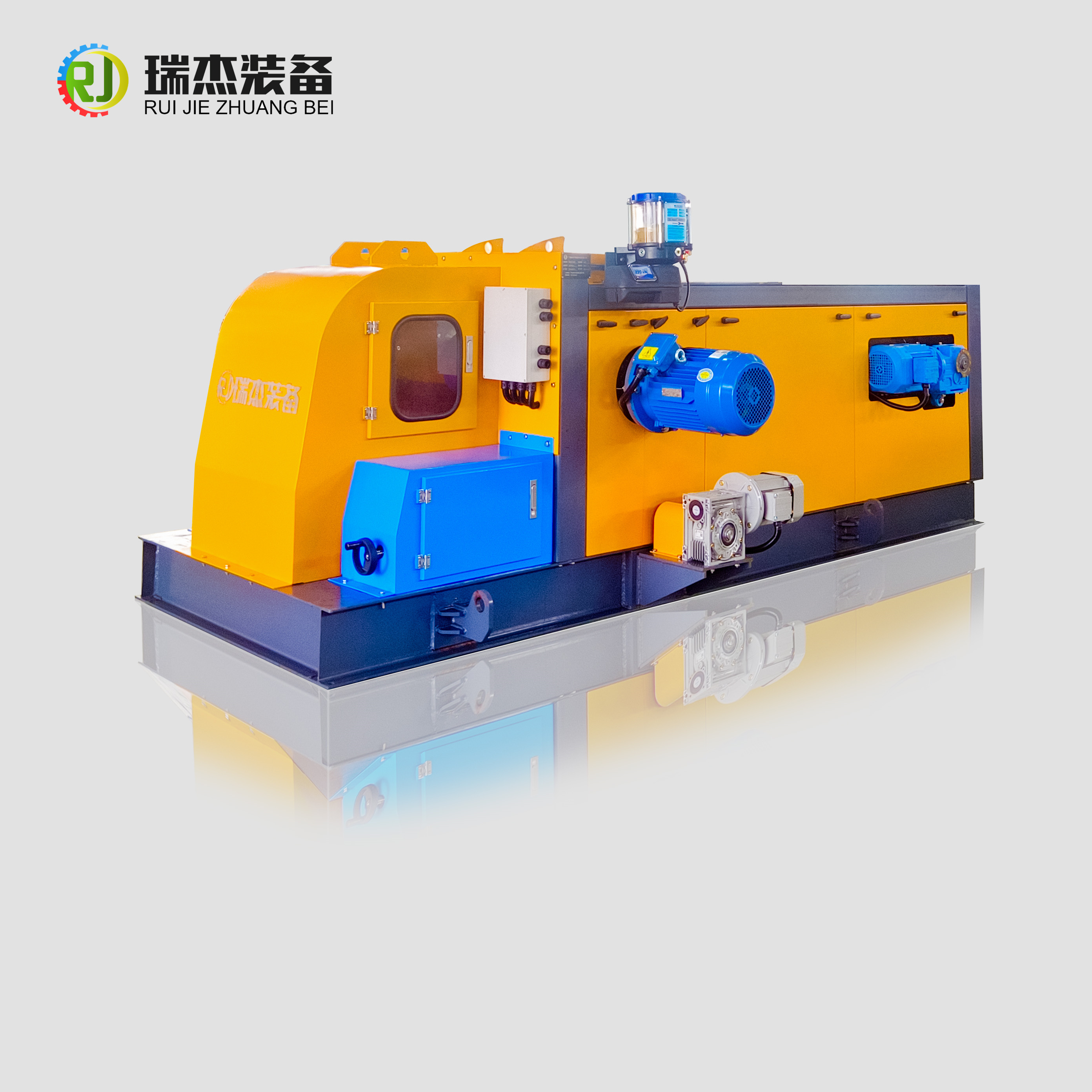

Ruijie Eddy Current Separator is a cutting-edge machine designed specifically for non-ferrous metal recovery. While widely used in mining, slag processing, and construction waste recycling, its role in UBC recycling is transformative. It excels at separating aluminum from mixed waste streams, achieving high-purity outputs that maximize the value of recycled materials. For instance, it efficiently isolates aluminum cans, pull-tabs, and even shredded aluminum fragments from plastics, glass, and organic waste.

Mining: Helps in separating valuable metallic minerals from ores.

Slag sorting: Assists in recovering useful metals from industrial slags.

Construction waste: Enables the extraction of recyclable metals from discarded building materials.

Recycling industry: Plays a crucial role, especially in achieving outstanding results in aluminum - related material recycling.

The working principle of the eddy current separator relies on electromagnetic induction:

1. As the conveyor belt of the separator transports the mixture containing aluminum materials, the magnetic rotor inside generates a strong alternating magnetic field.

2. This magnetic field induces eddy currents within the aluminum materials.

3. The induced eddy currents create their own magnetic fields, which interact with the original magnetic field.

4. As a result, the aluminum materials are repelled and thrown out, effectively separating them from non - magnetic materials.

To maximize efficiency in UBC recycling:

Pre-sort waste: Remove large non-metallic items to avoid clogging the machine.

Adjust rotor speed: Tailor the magnetic field strength to the size and conductivity of aluminum pieces.

Use vibration feeders: Ensure even distribution of materials onto the separator’s conveyor belt.

Post-sorting checks: Combine eddy current separation with optical sorters or magnets for final quality control.

Ruijie’s technology stands out for several reasons:

High precision: Achieves up to 99% aluminum recovery rates.

Scalability: Processes 5–15 tons of material per hour, ideal for large operations.

Durability: Built with wear-resistant components for long-term use.

Energy efficiency: Low power consumption reduces operational costs.

Versatility: Handles diverse materials, from beverage cans to auto shredder residue.

Starting a UBC recycling business demands a balance between cost-efficiency and output quality. Manual sorting alone cannot meet modern recycling demands, but integrating a Ruijie Eddy Current Separator into your workflow revolutionizes the process. By automating aluminum separation, you reduce labor costs, improve material purity, and boost profitability. As circular economy practices gain momentum, investing in advanced separation technology positions your business as a leader in sustainable resource recovery.

Whether you’re processing household UBC or industrial metal scrap, the Ruijie Eddy Current Separator offers a future-proof solution to turn waste into wealth—one aluminum can at a time.

#eddy current separator #Eddy current sorting machine #Aluminum recycling #AluminumSeparation #eddycurrenttestingmachine #eddyseparator #magneticseparatormachine #EquipmentManufacturer