Notifications

5 minutes, 9 seconds

-19 Views 0 Comments 0 Likes 0 Reviews

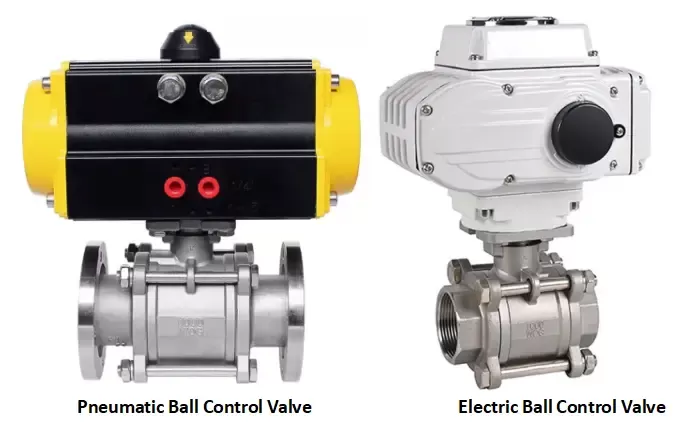

In industrial systems, control valves are vital for regulating the flow of fluids, ensuring efficiency, safety, and precision across operations. Among the various valve types, ball control valves stand out for their reliability, tight sealing, and adaptability. When it comes to actuation, electric and pneumatic ball control valves are the two most widely used. This article explores their differences, weighing the pros and cons to help you choose the right solution for your application.

Ball control valves use a rotating spherical ball with a hollow center to regulate flow. Turning the ball aligns or misaligns the hole with the flow path, enabling smooth modulation from full flow to complete shut-off. Their durable construction and low maintenance make them ideal for industries like:

Oil & gas

Chemical processing

Water and wastewater treatment

Power generation

Electric ball valves are powered by an electric motor, which rotates the ball based on control signals. These valves are commonly integrated into automated systems where precision and remote operation are priorities.

High Precision

Electric actuators allow for fine adjustments, ensuring accurate control in flow-sensitive applications.

Seamless Automation

Easily integrates with digital control systems (e.g., PLC, SCADA), enabling remote monitoring and operation.

Energy Efficient

Once positioned, electric actuators consume minimal power, offering better energy savings over time than systems requiring continuous input.

Higher Upfront Costs

Electric actuators are generally more expensive than pneumatic ones and may have higher maintenance costs.

Slower Actuation Speed

Response time can be slower, making them less suitable for rapid cycling applications.

Complexity

Electric components can be sensitive to environmental conditions and may require specialized maintenance.

Pneumatic ball valves operate using compressed air to move the actuator, rotating the valve ball to adjust flow. They're widely used in facilities where speed, reliability, and cost-efficiency are crucial.

Fast Response Time

Pneumatic actuators respond quickly to control signals, ideal for fast-paced processes.

Robust and Simple Design

Fewer moving parts and minimal electronics make them durable and easier to maintain.

Lower Initial Cost

More cost-effective, especially in plants already equipped with compressed air infrastructure.

Ongoing Air Consumption

Requires a continuous supply of compressed air, which can increase operational energy costs.

Noise

Pneumatic systems can be louder, which may be a concern in noise-sensitive environments.

Limited Precision

While reliable, pneumatic systems may lack the fine control needed for delicate flow modulation.

| Feature | Electric Ball Valve | Pneumatic Ball Valve |

|---|---|---|

| Actuation Speed | Moderate | Fast |

| Control Precision | High | Moderate |

| Energy Use | Low (after actuation) | High (continuous air consumption) |

| Integration | Excellent for digital systems | Simple manual or basic automation |

| Cost | Higher upfront | Lower initial investment |

| Maintenance | Moderate (requires electrical care) | Low (simple components) |

If your system requires tight control tolerances or integration with advanced automation platforms, electric ball valves are the better fit.

For operations where quick actuation and system resilience are key, pneumatic ball valves deliver superior performance.

Facilities with existing compressed air systems can economically leverage pneumatic valves, while those with electric infrastructure may benefit more from electric solutions.

Both electric and pneumatic ball control valves serve essential roles in industrial fluid control. Your choice should be guided by specific operational needs—whether that’s precision, speed, energy efficiency, or integration with existing systems. By understanding the strengths and limitations of each valve type, you can make a well-informed decision that improves process efficiency, minimizes downtime, and supports long-term performance.Know more about Google SEO Directory