Notifications

6 minutes, 41 seconds

-47 Views 0 Comments 0 Likes 0 Reviews

Control valves play a vital role in regulating fluid flow, pressure, and temperature across diverse industrial processes. With continual advancements in valve technology, modern control valves are engineered to meet the stringent demands of fossil power plants, oil and gas operations, and other challenging environments. These China Control Valves excel in semi-severe service conditions, often incorporating anti-cavitation or low-noise trim to address issues like erosion, noise, and vibration caused by high-pressure drops. Such robust designs ensure reliable performance, improved process control, and enhanced plant efficiency.

Typical applications range from heater drains and condensate water systems to steam services, spray water regulation, level control, pressure stabilization, and flow modulation. This versatility makes control valves indispensable in maintaining safe and efficient operations across numerous industries.

Modern control valves integrate the latest innovations to offer flexibility, durability, and simplified maintenance. The valve’s rigid body construction minimizes plug vibration, ensuring stable operation over the entire stroke. Designed to accommodate various trim options, the valve can be tailored for specific process needs. A key feature is the screwed seat design, which allows for straightforward repair and trim replacement, minimizing downtime and associated costs.

Multi-Spring Actuator Design

Improves hysteresis and dead band characteristics for precise, responsive control.

Proven Trim Design

Employs a single P-port with a drilled-hole cage optimized to enhance flow control while reducing noise.

Fail-Safe Modes

Offers fail-to-close and fail-to-open options to maintain safety and operational reliability in the event of air supply failure.

Screwed Seat Design

Facilitates easy access for inspection and maintenance by bonnet removal, streamlining service procedures.

Accessories

A wide array of options including positioners, limit switches, and solenoid valves are available to suit specific operational requirements.

Control valves provide numerous advantages for both general and specialized uses:

Tight Shutoff

Available with ANSI shutoff classes IV to VI, ensuring minimal leakage and compliance with strict process standards.

Versatile Actuation

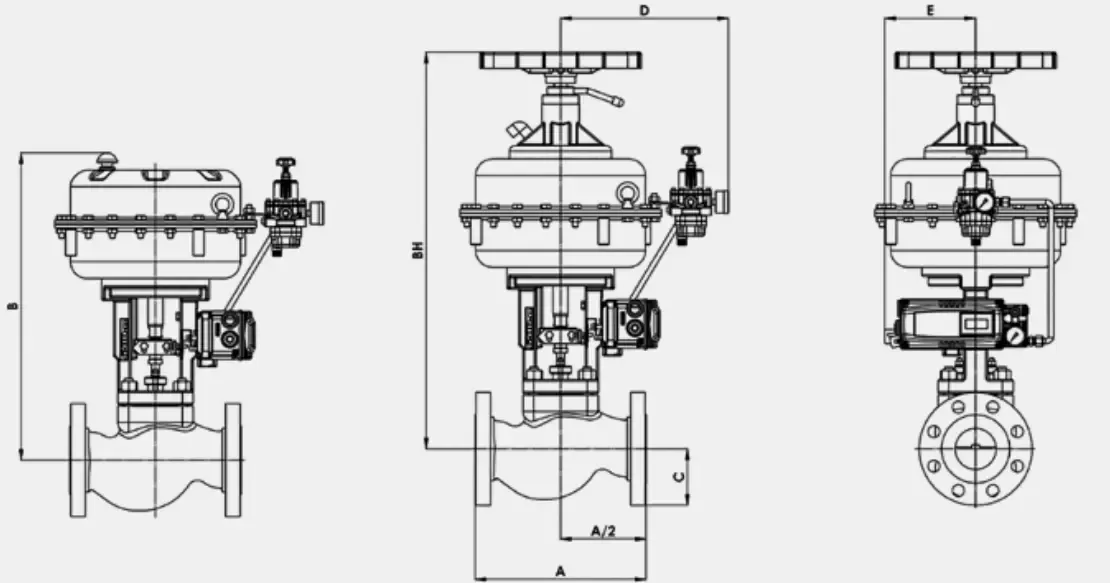

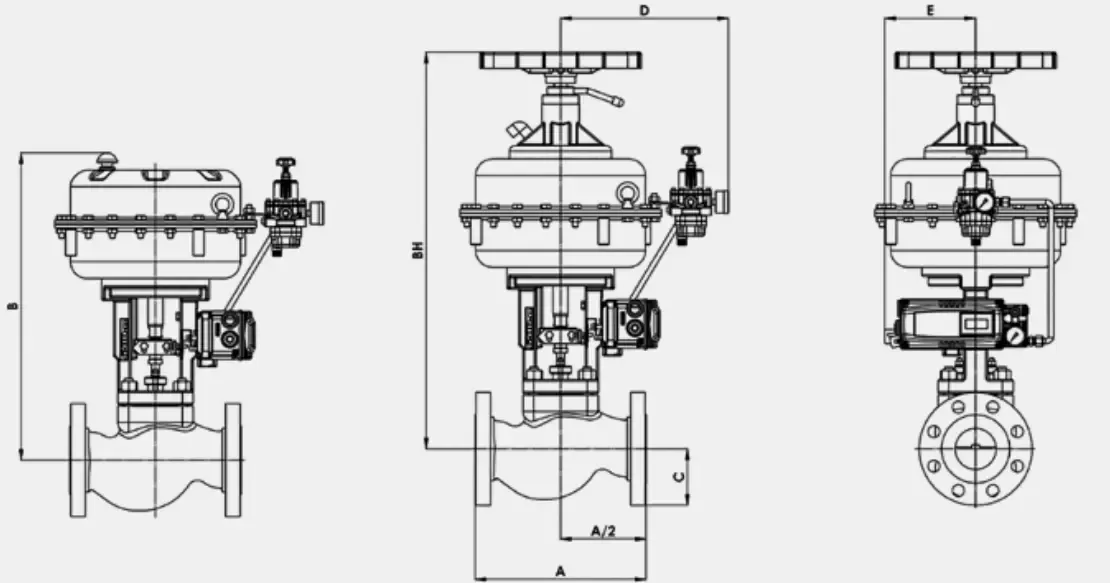

Supports pneumatic, electric, and top-mounted handwheel actuators for flexible operation.

Ease of Maintenance

Top-entry design enables rapid inspection and trim replacement, reducing downtime.

Flexible Trim Options

Quick interchangeability between reduced and full-sized trims, or linear and equal percentage flow characteristics, allows easy adaptation to changing process conditions.

Corrosion Resistance

Wide selection of body and trim materials supports use with corrosive fluids and sour gas, fully compliant with NACE standards.

Control valves find application in a broad spectrum of industrial processes, including:

Heater Drains

Regulate condensate removal to maintain heat transfer efficiency and prevent water hammer.

Condensate Water Systems

Control water levels to optimize steam cycle performance.

Steam Services

Manage steam flow and pressure in boilers, turbines, and related systems for safe and efficient operation.

Spray Water Systems

Precisely adjust spray water flow in cooling and desuperheating processes to maintain target temperatures.

Level Control

Maintain consistent fluid levels in tanks and vessels to avoid overflow or dry running conditions.

Pressure Control

Stabilize system pressure, protecting equipment and ensuring process stability.

Flow Control

Optimize fluid flow to enhance process efficiency and product quality.

Modern control valves are equipped with state-of-the-art features to boost reliability and efficiency:

Anti-Cavitation Trim

Reduces cavitation damage, noise, and vibration, prolonging valve life.

Low-Noise Trim

Minimizes operational noise without sacrificing control precision.

Digital Positioners

Provide accurate valve positioning and real-time feedback for enhanced control.

Smart Valve Technology

Integrates sensors and communication modules for remote monitoring, diagnostics, and predictive maintenance.

Material choice is critical for valve longevity and safety. Control valves are manufactured from carbon steel, stainless steel, alloy steels, and specialty alloys such as Hastelloy and Inconel, selected for corrosion resistance, erosion resistance, and high-temperature tolerance.

Compliance with industry standards such as NACE MR0175/ISO 15156 for sulfide stress cracking resistance, as well as ANSI, ASME, and API specifications, ensures valves meet rigorous safety, reliability, and interoperability requirements—particularly for sour gas and corrosive fluid services.

Maximizing control valve performance and lifespan requires careful installation and upkeep:

Correct Sizing

Proper valve sizing prevents excessive pressure drops, cavitation, and noise.

Proper Alignment

Ensures smooth operation and reduces premature wear.

Regular Inspection

Early detection of issues reduces risk of unexpected failures.

Timely Maintenance

Routine replacement of worn parts, lubrication, and cleaning maintain optimal valve performance.

Control valves are fundamental to precise and reliable process control in a multitude of industries. Innovations in design, materials, and technology have greatly enhanced their performance, durability, and maintainability. By effectively managing challenging conditions—such as high pressure drops, corrosive fluids, and sour gases—modern control valves support safer, more efficient, and sustainable operations in fossil power plants, oil and gas facilities, and beyond.

Choosing the right control valve and adhering to best practices in installation and maintenance ensure optimal plant performance, reduced operational costs, and long-term reliability. As industrial demands evolve, control valves will continue to drive innovation in process control technology.Know more about Google SEO Directory