Notifications

7 minutes, 50 seconds

-18 Views 0 Comments 0 Likes 0 Reviews

In the automotive industry, the demand for components that combine strength, precision, and reliable fit has never been higher. Injection molded auto parts are a cornerstone of modern vehicle design, offering designers and manufacturers the ability to produce complex parts that meet rigorous safety and performance standards. These parts are essential not only for structural integrity but also for aesthetic appeal and functional reliability, especially in critical areas such as safety systems, interior fixtures, and exterior panels. Achieving superior strength and perfect fit requires advanced injection molding techniques, high-quality materials, and meticulous engineering, making the process a key factor in the production of vehicles that are safe, durable, and comfortable.

The balance between strength and fit in automotive injection mold parts is vital for ensuring vehicle safety, longevity, and customer satisfaction. Components exposed to mechanical stress, vibration, and external impacts must be robust enough to withstand everyday wear and tear, while also fitting seamlessly into the assembly to maintain the overall vehicle integrity. Poorly fitting parts can lead to rattles, leaks, or failure over time, compromising vehicle safety and reliability. Conversely, parts that lack the necessary strength can crack, warp, or break under strain. High-quality injection molding resolves these challenges by producing parts that are both structurally sound and precisely dimensioned, thereby enhancing the overall performance and aesthetic appeal of vehicles.

The foundation of injection molded parts with superior strength and fit lies in the selection of advanced materials. Modern thermoplastics and thermoplastic composites, such as reinforced polypropylene, ABS, and polycarbonate blends, are engineered for high-performance applications. These materials offer excellent impact resistance, high tensile strength, and resistance to extreme temperatures and UV radiation, ensuring longevity in diverse driving conditions. Reinforcements like glass fibers further enhance mechanical properties, creating parts that can withstand significant loads without compromising their shape or integrity. Carefully selecting materials suited for specific applications is essential in ensuring that the finished parts deliver exceptional durability, all while maintaining tight dimensional accuracy for perfect fit.

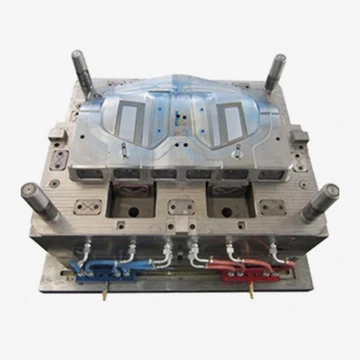

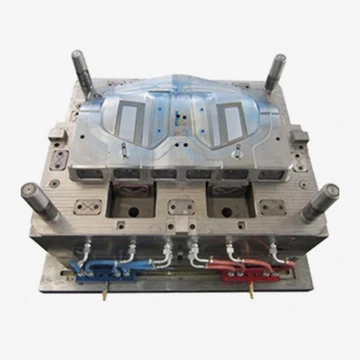

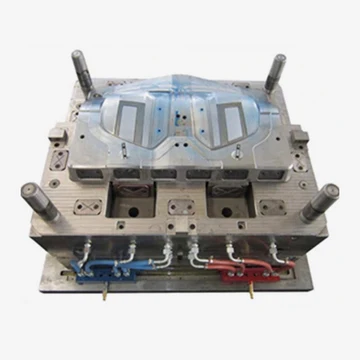

To produce injection molded parts that exhibit superior strength and a flawless fit, manufacturers employ cutting-edge engineering and advanced manufacturing techniques. Precision mold design involves sophisticated 3D computer modeling and simulation to predict how materials will flow, cool, and solidify. Optimizing gating and cooling channels ensures uniform molding, which minimizes internal stresses and warping. High-precision CNC machining and EDM processes create molds with extremely tight tolerances, enabling the production of parts with consistent quality every time. Automated processes, such as robotic injection and inline quality checks, further improve accuracy and repeatability. These technological advancements allow for the creation of highly durable parts that conform precisely to design specifications, ensuring perfect assembly and optimal performance.

Maintaining high standards in injection molded auto parts requires rigorous quality control at every stage of production. Inspection procedures include dimensional checks using coordinate measuring machines, visual assessments for surface finish and uniformity, and functional testing to simulate real-world usage. Non-destructive testing methods reveal internal flaws such as voids or weak spots that could compromise strength. Additionally, parts are subjected to environmental testing—exposing them to temperature extremes, vibration, and chemical exposure to evaluate performance under real operating conditions. These comprehensive quality checks help identify potential issues early, ensuring that each batch of components meets the strict safety and durability standards required by automotive manufacturers. This relentless focus on quality guarantees that every part produced with superior strength and fit performs reliably throughout its service life.

Achieving the perfect combination of strength and fit begins with thoughtful design. Engineers utilize advanced CAD software to develop parts with optimal wall thickness, ribbing, and reinforcements to strengthen key stress points. The design process also focuses on minimizing internal stresses that can cause warping or cracking, especially during cooling. Features such as interlocking surfaces, snap fits, and alignment tabs are incorporated to ensure accurate assembly and ease of installation. For exterior panels and interior fixtures, surface textures and matching mold finishes are carefully integrated to deliver an aesthetically pleasing appearance alongside functional performance. The iterative process of design, simulation, and prototype testing ensures that the final parts not only fit perfectly but also withstand the rigors of automotive use without failure.

As automotive technology advances and vehicle architectures become more complex, the demand for injection molded parts with even higher strength, better fit, and lighter weight will grow. Innovations such as multi-material molding, which combines different plastics in a single component, and fiber-reinforced composites are paving the way for stronger, more versatile parts. Additive manufacturing and rapid prototyping techniques enable quicker iterations in the design process, allowing for optimized shapes and functionalities. Sustainability considerations are also shaping future developments, with a focus on recyclable materials and eco-friendly processing methods. These advancements will enable automakers to manufacture safer, more efficient, and visually appealing vehicles, all while maintaining the highest standards of quality and performance.

In conclusion, injection molded auto parts that boast superior strength and perfect fit are essential for the modern automotive industry. From advanced materials and precise engineering to rigorous quality control and innovative designs, the journey toward creating durable, reliable, and perfectly fitting components continues to evolve. These parts not only improve vehicle safety and longevity but also enhance aesthetic appeal and overall driving experience, supporting the industry’s ongoing pursuit of excellence. As technology and materials science progress, the production of high-performance injection molded components will remain a driving force behind automotive innovation and quality.