Notifications

4 minutes, 28 seconds

-97 Views 0 Comments 0 Likes 0 Reviews

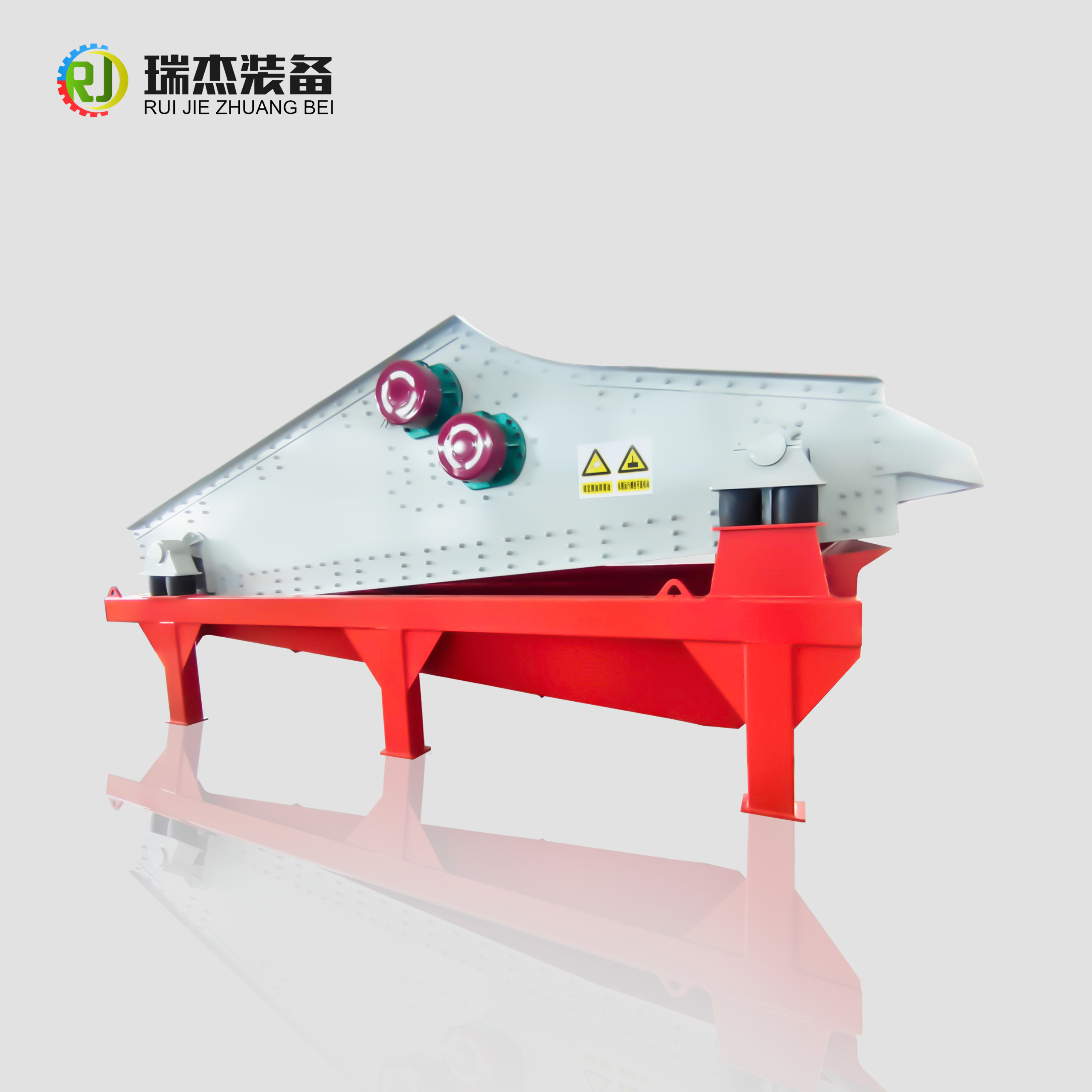

In industrial machinery, the Ruijie Dewatering Screen offers efficient solid-liquid separation. Let’s quickly explore its core aspects.

A dewatering screen separates solids from liquids via vibration and stacked meshed screens. Ruijie’s version, crafted with advanced tech and quality materials, excels in screening, dewatering, and desliming.

The Ruijie Dewatering Screen demonstrates its versatility across a wide array of industries:

Wastewater Treatment: Crucial in municipal and industrial wastewater treatment. In municipal sewage, it captures suspended solids at the pretreatment stage, protecting downstream equipment and reducing treatment load. For industrial wastewaters from food processing or chemical plants, it separates pollutants and by-products, aiding in material recovery and ensuring compliance with discharge standards.

Mining: Separates valuable ores from waste materials, reducing water content in concentrates and enhancing overall mining efficiency. In gold mining, for example, it helps isolate gold - bearing ores from tailings.

Construction Materials: In sand and gravel plants, it processes washed sand, removing excess water to produce high - quality aggregates for construction projects. This ensures the strength and durability of concrete and other building materials.

Slag Processing: At slag processing plants, it efficiently handles the dewatering of slag, facilitating the separation of solid particles from residual moisture, which is essential for further recycling or disposal.

Coal Processing: In coal preparation plants, the screen is used for coal slime recovery, helping to reclaim valuable coal fines from slime water, thus improving coal utilization and reducing waste.

Tailings Management: In mineral processing plants, it enables tailings dry discharge, minimizing the environmental impact of tailings disposal by reducing the volume of liquid waste and stabilizing the solid residues.

Medicinal Herb Dehydration: For medicinal herb dehydration, it helps in quickly removing moisture from harvested herbs. This preserves their quality and extends shelf life, ensuring the efficacy of herbs is maintained for pharmaceutical or traditional medicinal use.

Organic Fertilizer Production: In the production of organic fertilizers, it dewaters organic materials. By optimizing the drying process, it enables efficient fertilizer production — reducing excess moisture speeds up composting or pelletizing, leading to higher - quality, ready - to - use organic fertilizers.

Crop Dehydration: It can also be applied to crop dehydration. After harvest, removing moisture from fresh produce ensures it’s ready for storage or further processing (like canning, freezing, or milling). This prevents spoilage, preserves nutritional value, and streamlines post - harvest supply chain workflows.

Ruijie Dewatering Vibrating Screen boast several key advantages. Their high - efficiency design, with a powerful vibrating motor and optimized screen surface, processes large volumes swiftly, boosting productivity. Advanced screening technology guarantees accurate separation, yielding drier solids and cleaner liquids.

Durability is a strong suit, with robust and corrosion - resistant construction. This allows the vibrating screen to operate in harsh conditions, minimizing maintenance and extending lifespan. The user - friendly interface simplifies operation, reducing training needs. Environmentally, they cut water usage and waste, promoting sustainable industrial practices.

In summary, Ruijie Dewatering Screens combine efficiency, durability, and eco - friendliness. Their wide applications and numerous benefits make them an excellent choice for industries aiming to optimize operations and enhance productivity.

#dewatering screen #vibrating screen #conveying machine #dewatering screen machine