Notifications

3 minutes, 38 seconds

-37 Views 0 Comments 0 Likes 0 Reviews

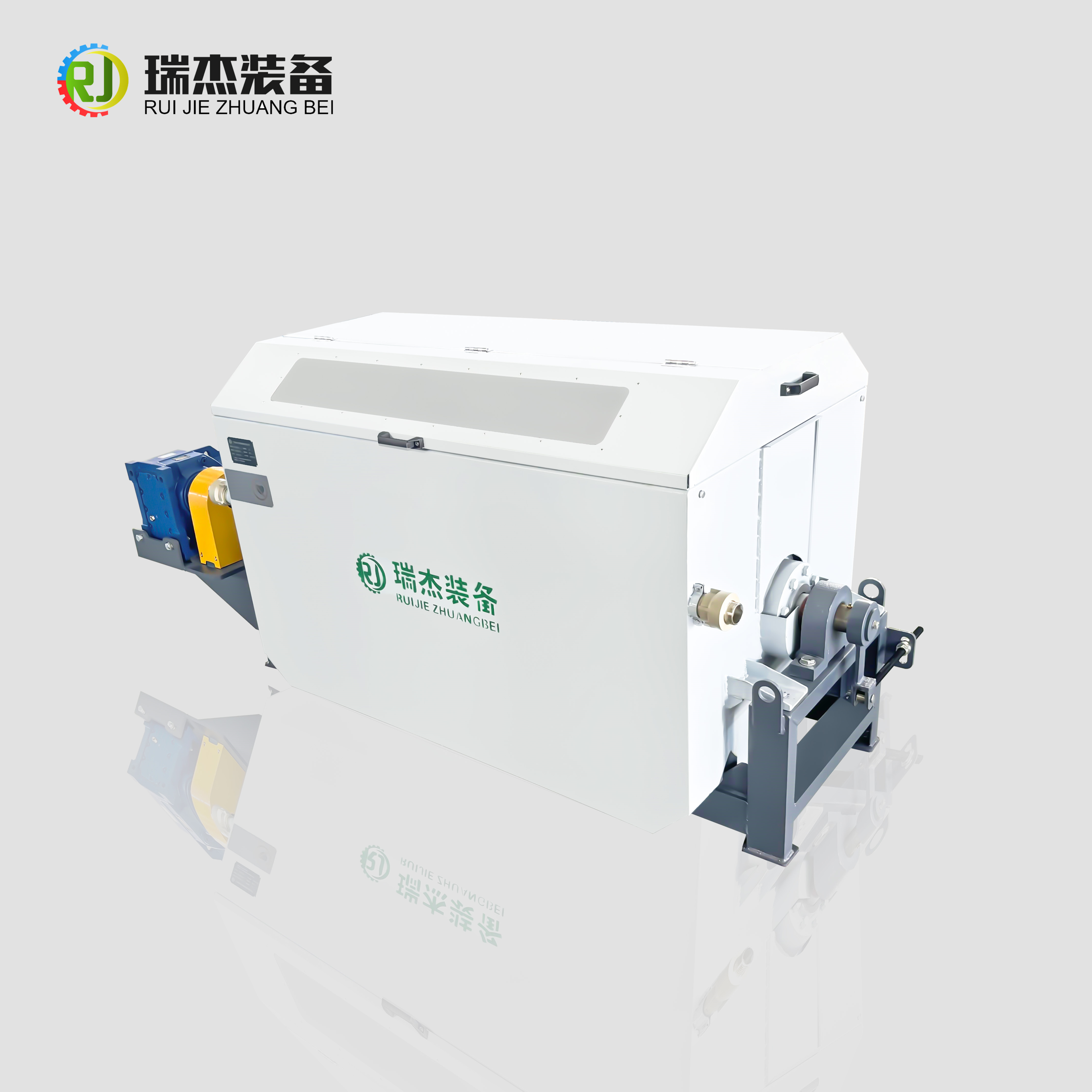

In the constantly evolving field of industrial machinery, permanent - magnet drums have become an indispensable and highly efficient, low - cost preferred solution for material separation.

These drums harness the power of permanent magnets, offering efficiency and versatility that other sorting equipment cannot match, making them a hot - selling product across various industries.

In mineral processing, especially iron ore separation, magnetic drums are vital for extracting valuable magnetic minerals from ores. Mining giants in Australia and Brazil rely on these drums to process thousands of tons of ore daily, improving ore grade and reducing waste. In the coal industry, magnetic drums remove ferromagnetic impurities, safeguarding downstream equipment and boosting coal quality.

In the food and beverage industry, sanitary magnetic drums are crucial for product safety. They efficiently eliminate metal contaminants from ingredients and finished products, ensuring compliance with strict global food safety regulations. Similarly, in chemical and pharmaceutical manufacturing, magnetic drums aid in catalyst separation and pharmaceutical purification, enabling catalyst recycling and high-purity product production.

In the environmental protection sector, magnetic drums play a significant role in wastewater treatment. When combined with magnetic seed enhanced separation techniques, they effectively remove heavy metals and magnetic particles from industrial and municipal wastewater, helping meet tough environmental standards and promoting water resource recycling.

· Strong Magnetic Performance and High-Efficiency Separation

· Simple Structure and Low Maintenance Cost

· Energy-Saving and Low Operating Costs

· Strong Adaptability and Flexible Application

· Safe, Reliable, and Environmentally Friendly

· No Magnetic Leakage Risk

· Long Service Life and High Cost-Effectiveness

· Stable Permanent Magnets

Permanent magnet drums have become ideal equipment for removing magnetic impurities and recycling resources in industrial fields due to their high-efficiency separation, energy conservation, low consumption, and simple structure. With the continuous advancement of permanent magnet material technology, such as the development of magnets with higher coercivity and temperature resistance, their application scenarios will further expand, playing a greater role in emerging fields such as new energy and environmental protection.

When selecting a permanent magnet drum, it is necessary to comprehensively design the solution based on material characteristics (such as magnetic properties, particle size, humidit), and processing capacity to achieve optimal separation effects.

Contact Ruijie Slag Equipment for More Detailed Magnetic Separation Information.

https://www.ruijie-equipment.com

Mobile/WhatsApp: +8617878005688

Email:R01@ruijie-equipment.com