Notifications

3 minutes, 4 seconds

-28 Views 0 Comments 0 Likes 0 Reviews

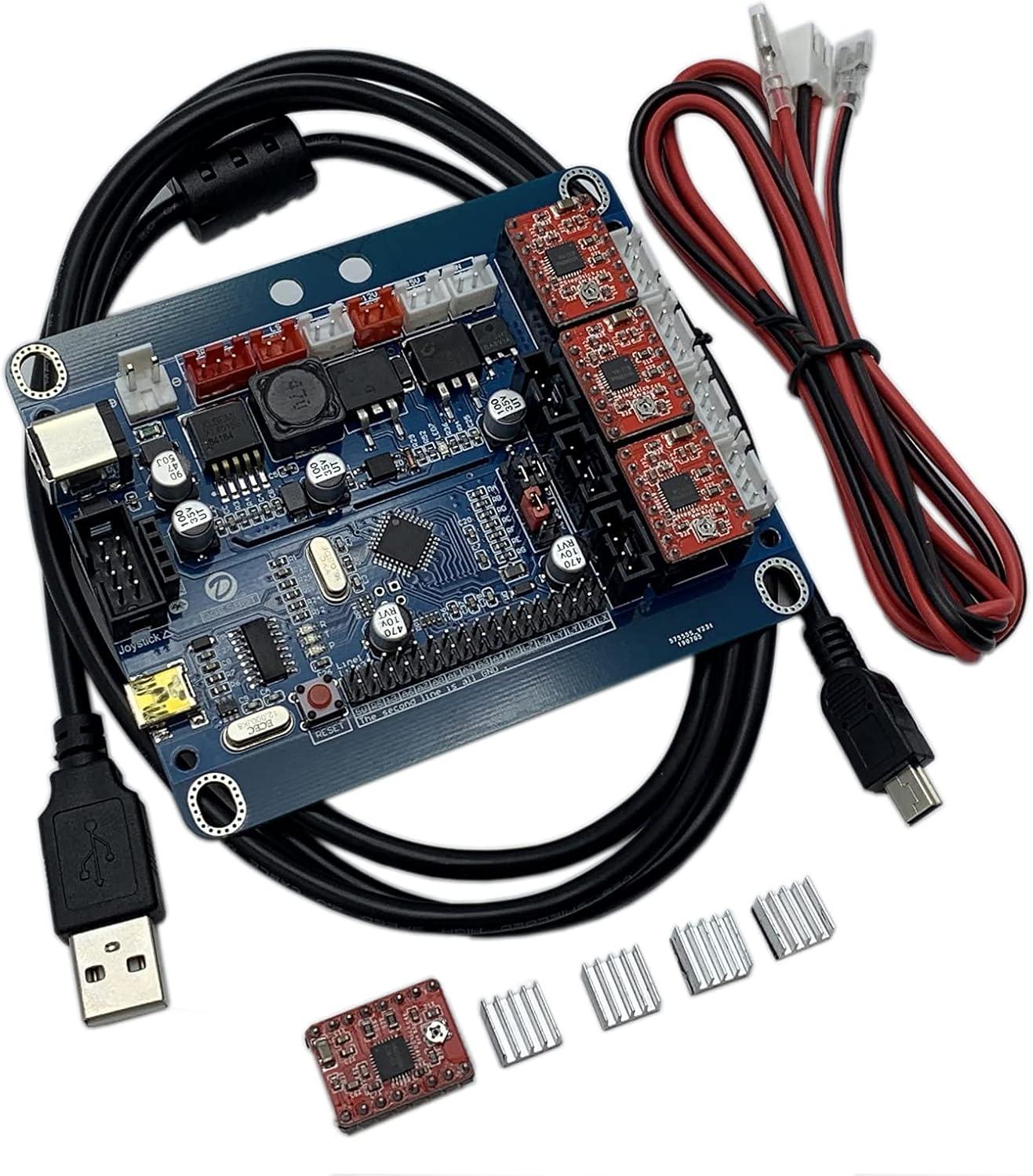

Precision is paramount in modern fabrication. Each part needs to be made correctly, no matter how tiny it is. CNC controllers are the brains behind the machines that fabricate parts with ultimate quality.

CNC stands for Computer Numerical Control. CNC means that machines create operations based on digital instructions and are, therefore, capable of reproducing complicated designs with consistency. Without CNC-type controllers, the whole of manufacturing would become a drudgery and prone to errors.

With these types of controllers, operators can input a design into the machine, and then the system guides the machine precisely along with the pattern. This is very important in any field where precision is an absolute demand: like aerospace, automotive, and electronics.

There are multiple features that make these controllers useful information. It can control anything from the speed and direction of a machine to pressure and depth of cuts made by the machine so that the finished product is made precisely to design. With the efficient integration of software and hardware, the process is guaranteed to be faultless.

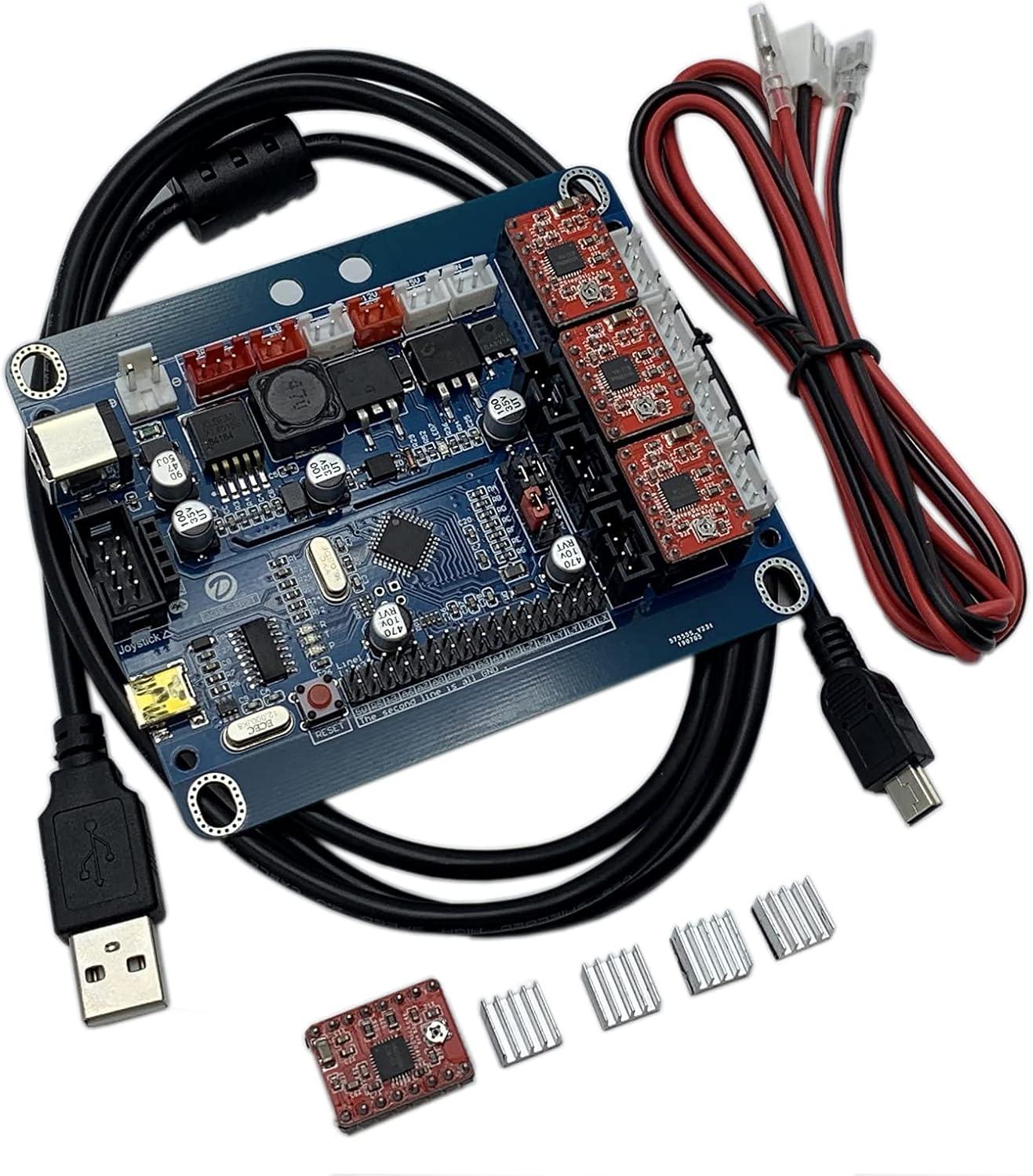

Therefore, having fast production and high standards demand from businesses in the present, and CNC controller has been able to set challenges to meet manufacturers' demand. They make it possible to produce parts at high speed, low cost, and with reduced errors, thus meeting a definite reduction in waste.

CNC controllers continue evolving with changing technologies. The integration of IoT and AI into CNC systems is transforming the mode of communication and operations of machines. Intelligent these controllers are capable of real-time diagnostics, predictive maintenance, and auto-adjustments, thereby improving productivity and reducing downtime. In doing so, manufacturers can remain on top of the competition, ever ensuring their equipment operates optimally.

The diversity of CNC controllers, however, goes much beyond mere manufacturing. Such systems are applicable in industrial fields spanning from medical devices manufacturing to bespoke furniture designing. The capacity to program machines and modify them to perform specific jobs has revolutionized making products, offering a realm of infinite opportunities for innovation and growth.

MELRIYA Technical Solutions L.L.C strives to provide CNC solutions that will give a competitive advantage to businesses for efficiency and precise achievement of their production goals.