Notifications

4 minutes, 23 seconds

-2 Views 0 Comments 0 Likes 0 Reviews

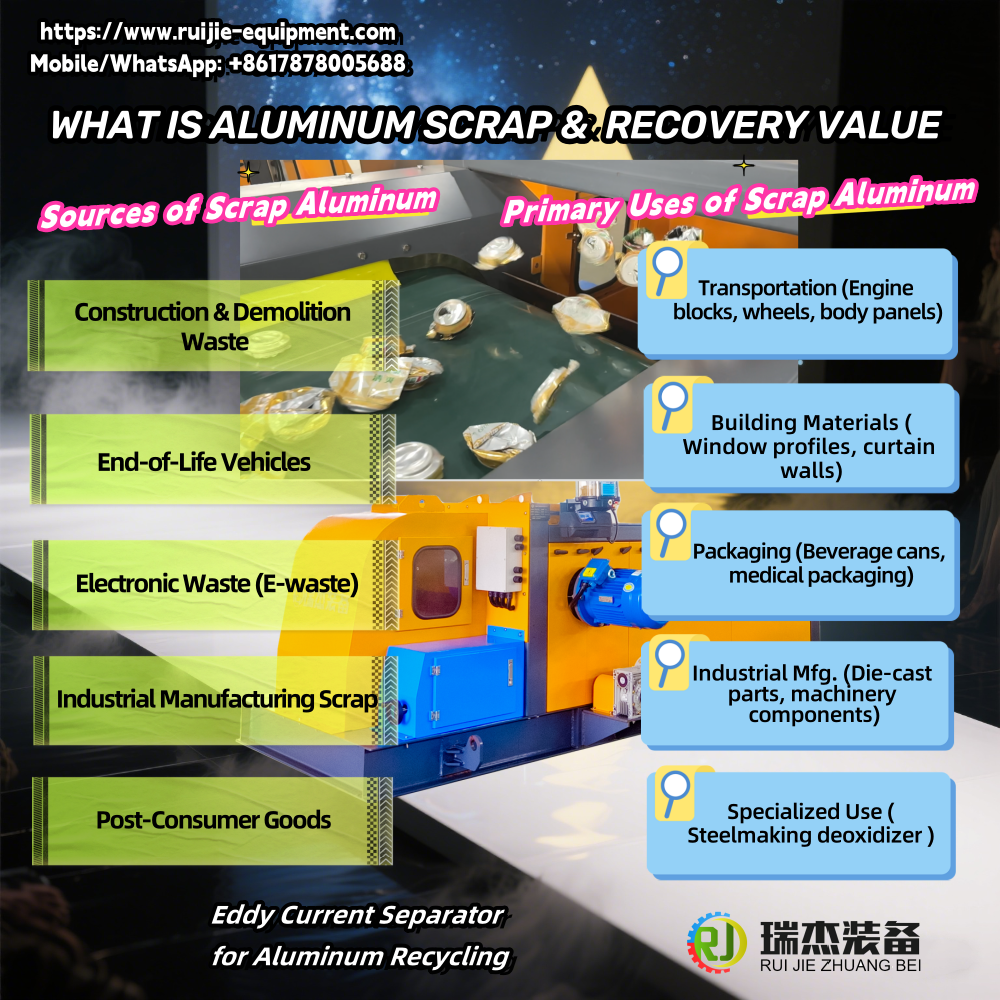

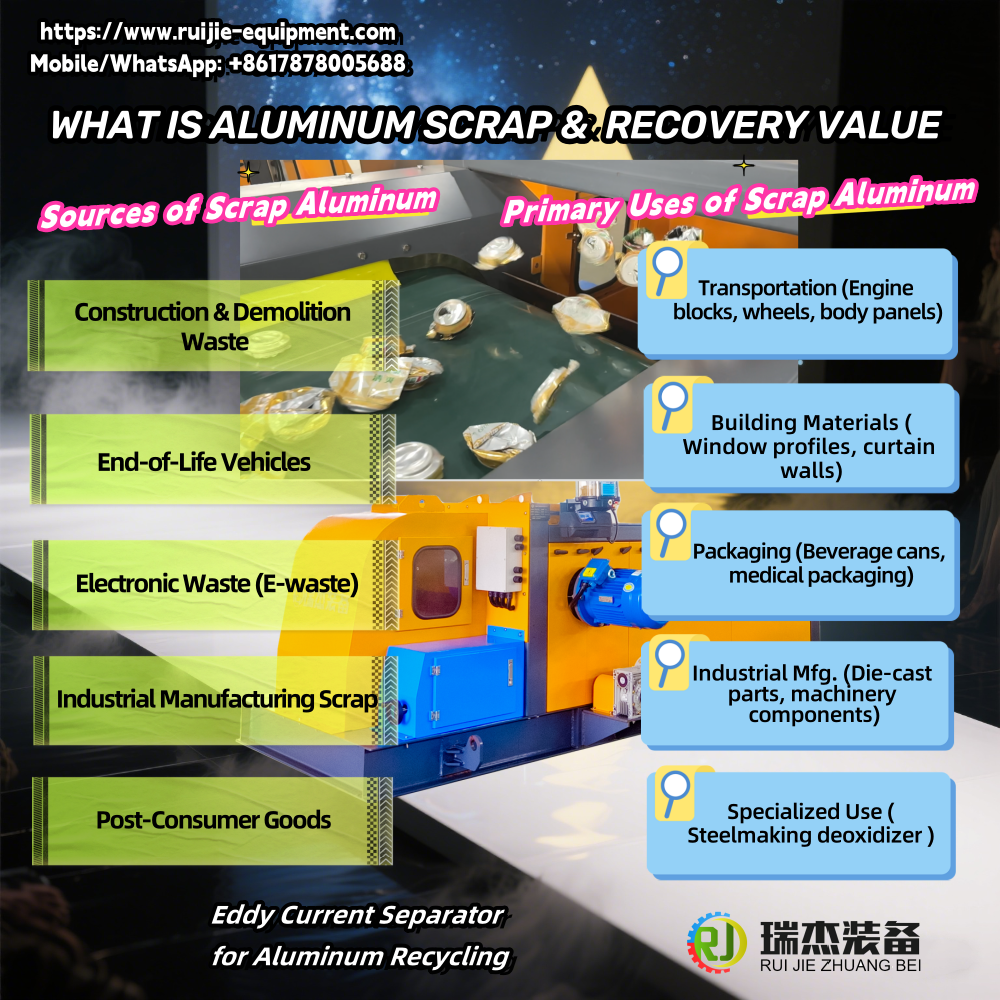

Aluminum scrap refers to discarded aluminum materials that can be recycled and reprocessed into new products.

Scrap aluminum comes from diverse sources:

· Construction & Demolition Waste: Window/door frames, curtain walls, roofing, pipes.

· End-of-Life Vehicles: Engine parts, wheels, body panels, aircraft components.

· Packaging: Beverage cans, food cans, foil trays, bottle caps (especially high recycling rate for cans).

· Electronic Waste (E-waste): Computer casings, heat sinks, cables, appliance parts.

· Industrial Manufacturing Scrap: Turnings, stamping scraps, foundry rejects.

· Post-Consumer Goods: Discarded cookware, furniture parts, decorations.

Recycled aluminum is primarily remelted to produce secondary aluminum:

|

Application Sector |

Specific Products |

Key Advantages |

|

Transportation |

Engine blocks, wheels, body panels |

Lightweighting & emission reduction(Critical for EVs) |

|

Building Materials |

Window profiles, curtain walls |

Corrosion resistance (50+ years service life) |

|

Packaging |

Beverage cans, medical packaging |

Food-safe recycling tech maturity |

|

Industrial Mfg. |

Die-cast parts, machinery components |

30% lower cost vs. primary aluminum |

|

Specialized Use |

Steelmaking deoxidizer (4-6kg Al per ton steel) |

Enhanced steel purity |

After being crushed into a certain size by a crusher, eddy current separator can separate and recover the scrap aluminum from mixed waste streams:

1. Feed Preparation: Mixed waste is shredded and screened for size uniformity.

2. Material Conveyance: Material is evenly fed onto a high-speed conveyor belt wrapping around a rotating drum.

3. Magnetic Field Generation: A rapidly rotating array of permanent magnets (or an AC electromagnet) inside the drum creates a strong alternating magnetic field.

4. Eddy Current Induction: When conductive metals (Al, Cu) pass through this field, eddy currents are induced within them.

5. Repulsion & Ejection: These eddy currents generate their own opposing magnetic field, creating a strong repulsive force (Lorentz force) that physically ejects the metal particle.

6. Separation & Collection: Ejected non-ferrous metals (Al, Cu) land in a separate collection bin; non-conductors (plastic, glass, rubber) follow their natural trajectory into another bin.

Scrap aluminum commands significant value, influenced by several factors:

1. Price Basis: Closely tied to the London Metal Exchange (LME) primary aluminum cash price, typically 70%-90% of LME.

2. Value Drivers:

· Energy Savings & Environment: Recycling uses only ~5% of the energy needed for primary production, drastically reducing CO2 emissions - high environmental premium.

· Metal Properties: Corrosion resistance, workability, strength, conductivity make aluminum inherently valuable to recycle.

· Circular Economy: Global push boosts demand and value through supportive policies.

· Supply & Demand: Strong demand from automotive lightweighting, EVs, solar, packaging; supply depends on collection rates.

· Grade Variation: Clean, sorted high-grade scrap (e.g., 6063 extrusions, clean painted siding) fetches the highest prices; mixed low-grade scrap (e.g., coated/dirty fragments) is lower.

Scrap aluminum is abundant and highly valuable. Ruijie eddy current separation enables efficient recovery, crucial for aluminum recycling loops. Aluminum's recyclability, energy savings, and strong demand underpin its core value in the scrap metal market. Promoting aluminum recycling is vital for resource conservation and environmental protection.

aluminum recycling aluminum scrap metal recycling scrap aluminum value eddy current separator eddy sorter